PRODUCT

Wood-Plastic Composite M.F.G Line

|

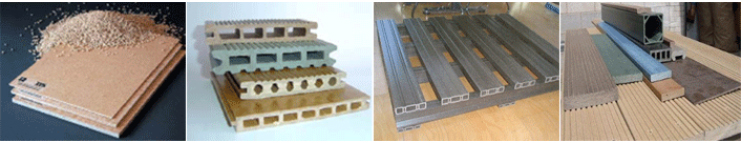

ShinKwang Engineering Co, developed newly the extrusion machines for Wood-Plastic composite profile and panel production with the technology and know-how as leader of extruders accumulated over 25 years. Its products, brand named “Poly-wood “ has a highly cost effective, friendly environmental, high chemical- mechanical performance, water & sound proofing, weather-resistant compared to existing one made by conventional machines so far.

◈ Features of Poly-Wood Manufacturing Line

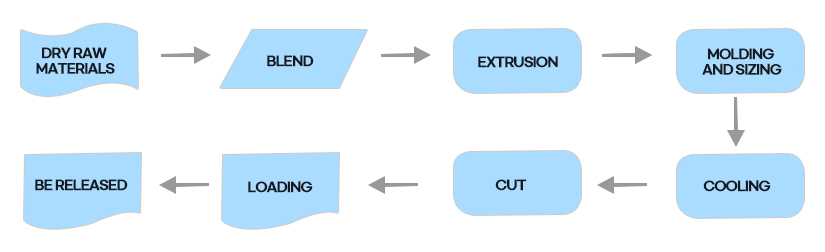

◈ Flow Chart

◈ Features of Poly-Wood Material manufactured by our line

◈ Applicable Uses

1. Profile type

◈ Standard Specification

1. Raw materialsPRODUCT

- Air Fiber Mattress Manufacturing Machine Line

- Single & Multi Blown Film Line

- High Quality Blown Production System

- Single & Multi Cast Film(Sheet) Line

- Twin Extruder Compounding Machine

- Automatic Winder

-

Plastic Related Facilities

- Foam Sheet Manufacturing Line

- Wood-Plastic Composite M.F.G Line

- Plastic Pipe Manufacturing Line

- Hot Melt Coation & Lamination Line

- Air Bubble Sheet Manufacturing Line

- Plastic Extrusion Zipper Tape M.F.G Line

- Profile Extrusiomn M.F.G Line

- Plastic Extrusion Experimental Instruments

- Edge Film Air Cooled Recycling Machine

- Pilot Equipment

- Melt Blown Production Line

- Double beams Nonwoven Fabric Making Machine