PRODUCT

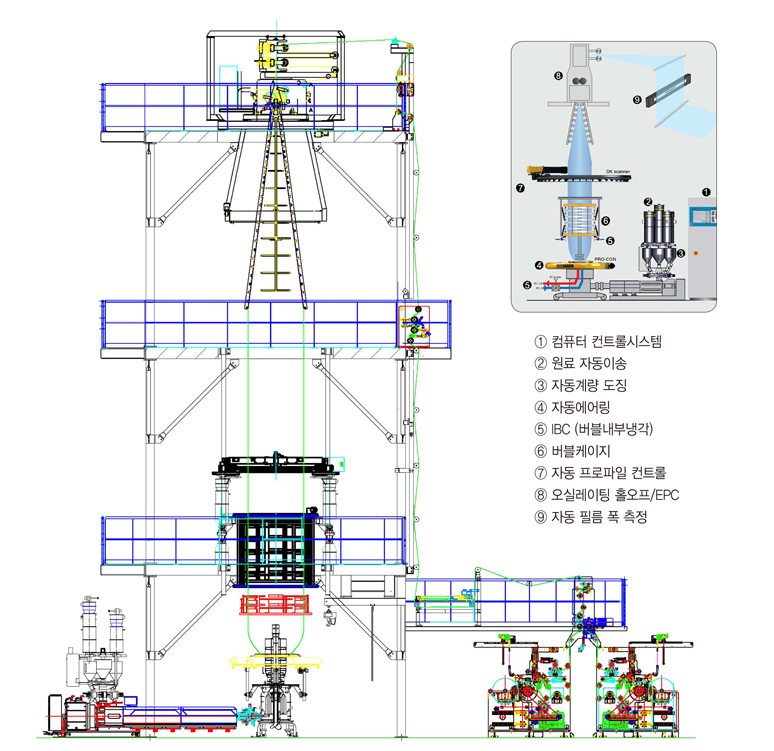

High Quality Blown Production System

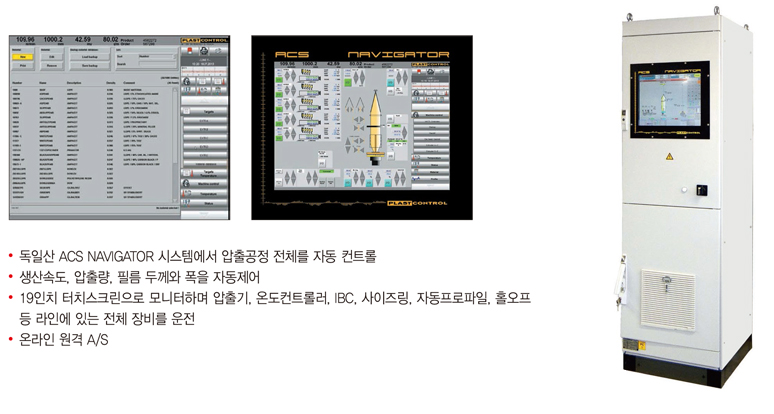

Full Auto Control System

|

Shinkwang Engineering, the leader in plastic film equipment production, introduces Germany's state-of-the-art automatic control devices to perform the same as the latest imported machines.

High-quality films can be produced with domestic extruders and dies of equal quality to expensive imported machines.

We offer a number of options that can be applied to your existing facilities.

Computer Control System

|

The entire equipment of the Blown Film Extrusion Line appears graphically simplified on one screen for intuitive and easy control.

Drive all systems with a single button via a wide touchscreen.

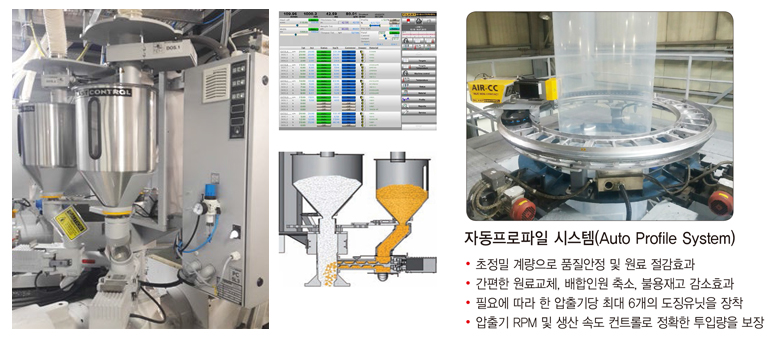

Auto Gravimetric Dosing System

|

The production of many varieties is increasing, and the market's demand for quality is becoming increasingly demanding.

We need to secure quality stability and reduce raw material cost and replacement time, so does your company have any countermeasures?

Solve with proven German technology already running thousands of systems around the world. Accurate measurement and dogging are important.

Experience state-of-the-art systems for optimal part design and real-time analysis and control of data from precise measuring devices with sophisticated software

Look at.

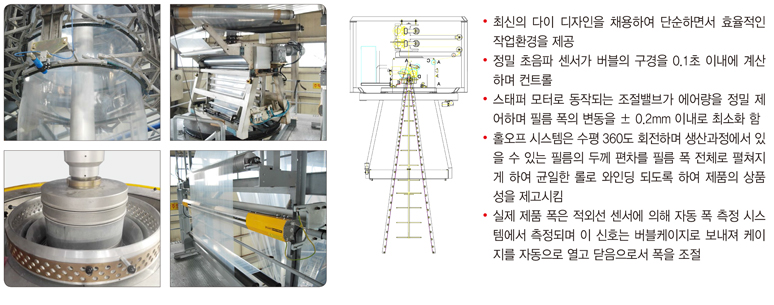

IBC & Oscillating Auto System

|

The IBC system injects a large amount of cold air into the bubble continuously, and circulates and releases the bubble immediately.

It significantly increases the production speed of the film by rapidly cooling it.

Modern German IBC control technology accurately measures tube width in real time and automatically controls the injection and discharge of air.

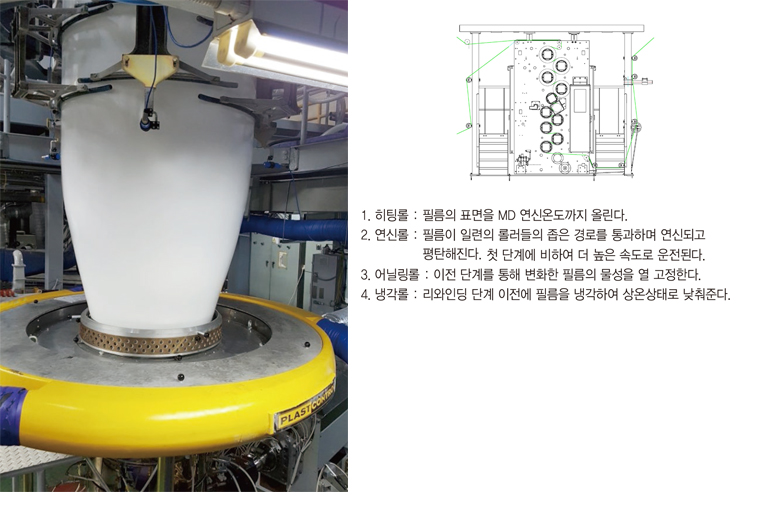

MDO (Machine Direction Orientation)

|

The MDO is a device used to improve the properties of a film. It consists of several roller groups with functions. Through the steps of heating, elongation, annealing, and cooling, the film is mechanical and immaterial. It dramatically improves .

PRODUCT

- Air Fiber Mattress Manufacturing Machine Line

- Single & Multi Blown Film Line

- High Quality Blown Production System

- Single & Multi Cast Film(Sheet) Line

- Twin Extruder Compounding Machine

- Automatic Winder

-

Plastic Related Facilities

- Foam Sheet Manufacturing Line

- Wood-Plastic Composite M.F.G Line

- Plastic Pipe Manufacturing Line

- Hot Melt Coation & Lamination Line

- Air Bubble Sheet Manufacturing Line

- Plastic Extrusion Zipper Tape M.F.G Line

- Profile Extrusiomn M.F.G Line

- Plastic Extrusion Experimental Instruments

- Edge Film Air Cooled Recycling Machine

- Pilot Equipment

- Melt Blown Production Line

- Double beams Nonwoven Fabric Making Machine